Capabilities

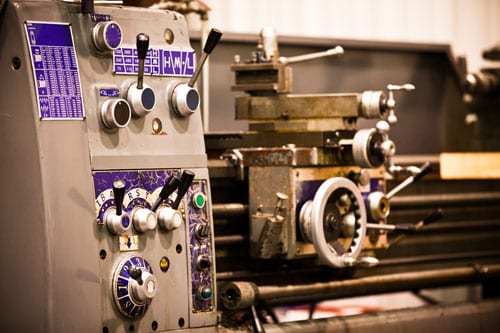

CNC Machining

Columbia Tool & Die regularly invests in contemporary CNC machining equipment to stay at the forefront of industry technology. A preventative maintenance schedule keeps the CNC equipment running as new.

The most current release of NX CAD-CAM software is used to create models and to generate multi-axis CNC mill and lathe toolpaths.

Columbia Tool & Die boasts a wide range of CNC mills and lathes including our flagship Haas VF11 CNC mill. The Haas VF11 features an enormous work envelope and 120 inches in X-axis travel.

Engineering

Our focal engineering competencies are in designing and manufacturing plastic injection molding tools, aluminum casting dies, metal stamping dies, work-holding fixtures, assembly, and inspection jigs.

Through a combination of analytical and creating thinking, we have helped guide many of our customers to solutions that have enhanced efficiency and productivity.

With a comprehensive knowledge of steels and polymers, we can confidently recommend the correct material for most mechanical applications.

Fabrication

Columbia Tool & Die can design, assemble and build complex and precise fabrications. We specialize in tight tolerance weldments that require machining after welding.

Industries We Work With

Automotive

Aerospace

Transportation

Medical Equipment

Nuclear Energy

Wind Energy

Defense

Equipment

CNC Turning Center

- Haas SL 30 Lathe, 20” turning capability, 36″ between centers, 12 station tool changer, 3000 rpm with 3” Spindle bore x 48″ bar feeder

- Haas ST-20 Lathe, 12” turning capability, 20″ between centers, 12 station tool changer, 4000 rpm with 2” Spindle bore

CNC Machine Center

- Haas VF-11/40 w/30 station tool changer, 120″ x 40″ x 30″ table capacity, 30hp 8,100rpm spindle, 4 axis capability

- Haas VF8 w / 24 station tool changer, 64″ x 40″ x 34″ table capacity, 30hp 10,000rpm spindle, 4 axis capability

- EC500 Horizontal Milling Center w / 40 station tool changer, 32″ x 20″ x 28″ work envelope, Dual pallet changer with 500 mm pallets, 8000-rpm 40-taper inline direct-drive spindle

- Haas VF4 w/20 Station tool changer, 50” x 20” x 25” table capacity, 30hp 8,100rpm spindle, 4 axis capability

- 2 x Haas VF2 w / 24 Station tool changer 14″ x 36″ x 24″ table capacity, 20hp 10,000rpm spindle, 4 axis capability

EDM Machines

- 3 x Creator CR-6C Sinkers 34″ x 20″ table with 18 inch Z height

Turning Equipment

- Atrump engine lathe 9″ x 60″ length w / Mitutoyo digital readout +0.0001

Milling Equipment

- Ganesh 10″ x 54″ table variable speed w /digital readout +0.0001

Grinding Equipment

- Proth Surface 24″ x 36″ table

- Kent Surface 8″ x 17″ table

- Acer Surface 6″ x 17″ table

Welding

- Miller Synchrowave 250 Amp water cooled TIG

- Miller Dynasty 200 Amp water cooled TIG

- Millermatic 252 200 Amp MIG

- Lincoln Square Wave 200 Amp MIG

- Therma Pack Plasma Cutter

Heat Treat

- Lucifer 24” x 36” x 12” capacity oven

- Tungsten Rocklinizer

Inspection

- SPI CV-600A Benchtop Hardness Tester

- Mitutoyo SJ-210 Surface Finish Tester

- Phase II Portable Digital Hardness Tester

- Cadillac Gage Set

- ID Micrometers up to 40”

- Mitutoyo PJ-300 Profile Projector Optical Comparator

- Gauge Pins, Gauge Blocks

Miscellaneous

- 24″ x 24″ 100 ton bedding press

- Cosen R-250NC Automatic Horizontal bandsaw 15” cut capability

- Dake Johnson JH10 Horizontal bandsaw 18” cut capability

- Horizontal and vertical belt sander

- Aceco 5 ton (full bay) overhead crane

- Caterpillar forklift truck 10,000 pound capacity

Get In Touch

Please complete the form below to have a representative contact you.